Introduction

Today, we’re diving into the complex world of thermal validation and learning how to keep those results squeaky clean. Yep, we’re talking about maximizing data integrity to ensure your temperature logs are as accurate as they are.

Why Bother?

First things first, why should you care about data integrity in thermal validation? Well, picture this: you’re monitoring the temperature of your precious samples, whether they’re vaccines, food products, or even sensitive chemicals. If your temperature logs aren’t accurate, you could be risking the integrity of those samples. Imagine the horror of discovering that your life-saving vaccine wasn’t stored at the right temperature – yikes!

Keeping it Simple- A Guide to Ensuring Data Integrity in Thermal Validation

Alright, so how do we maximize data integrity? It’s all about keeping it simple. Start by using reliable and calibrated temperature monitoring devices. Don’t try to reinvent the wheel with some fancy gadget that promises the moon – stick to what’s tried, tested, and true.

Consistency is Key

Next up, consistency is your best friend. Develop a standardized procedure for logging thermal validation results and stick to it like glue.

Whether it’s the frequency of temperature checks or the format of your log entries, make sure everyone on your team is on the same page.

Don't Forget the Basics

Okay, here’s a hot tip: don’t forget the basics. We’re talking about good old-fashioned record-keeping. Keep detailed records of every temperature reading, including the date, time, and location. It might seem tedious, but it’ll save you time when it comes to verifying the integrity of your data.

Back it Up, back it Up

Now, let’s talk about backups. No, not talking about saving your favorite cat videos (although that’s important too). I’m talking about backing up your temperature data. Store your logs in multiple locations – cloud storage, external hard drives, you name it.

That way, if disaster strikes (say, the lab gets hit by a rogue tornado), you’ll still have the precious data safe and sound.

Stay Vigilant

Last but not least, stay vigilant. Don’t just set it and forget it when it comes to monitoring temperature. Keep a close eye on monitoring devices; if something seems off, don’t hesitate to investigate. It’s better to catch a problem early on than to discover it when it’s too late.

Bonus Tips for Supercharging the Thermal Validation Game

Let’s take things up a notch with some bonus tips to take any thermal validation game to the next level.

- Training Your Team

Sure, you might be the data guru of the century, but what about the rest of your team? Make sure everyone involved in the thermal validation process is properly trained. From technicians taking temperature readings to analysts crunching the numbers, knowledge is power. Invest in training sessions and provide resources to ensure everyone understands the importance of data integrity and how to maintain it.

- Embracing Automation

Who’s got time to manually record temperature readings all day? Not you, my friend. Embrace automation wherever you can. Invest in temperature monitoring systems that can automatically log data at regular intervals. Not only does this save time, but it also reduces the risk of human error creeping into your logs.

But remember, automation isn’t a silver bullet. Thermal validation in pharmaceutical facilities presents unique challenges, such as maintaining consistent temperatures throughout large, complex environments and ensuring the accuracy of readings from a variety of monitoring devices. We’ll delve into these challenges and explore solutions in a future post on Common Thermal Validation Challenges in Pharma Facilities.

- Staying Compliant

Ah, regulations – the bane of every scientist’s existence. But hey, they’re there for a reason, right? Make sure your thermal validation practices are compliant with all relevant regulations and standards. Whether it’s FDA guidelines, ISO requirements, or local regulations, staying compliant not only keeps you out of trouble but also ensures the quality and reliability of your data.

- Conducting Regular Audits

Just like your annual physical exam, regular audits are essential for maintaining good health – in this case, the health of your data integrity. Schedule regular audits of your thermal validation processes to identify any potential weaknesses or areas for improvement. And hey, don’t be afraid to bring in an external auditor for a fresh perspective.

- Continuous Improvement

Last but not least, never stop striving for improvement. The world of data integrity is constantly evolving, so it’s essential to stay ahead of the curve. Keep an eye on emerging technologies and best practices and be willing to adapt and evolve your processes accordingly. Remember, the quest for data integrity perfection is a journey, not a destination.

- Documenting Everything

Ah, the power of documentation! It may seem like a mundane task, but trust me, it’s a game-changer regarding data integrity. Document every step of your thermal validation process, from calibration procedures to troubleshooting efforts. Not only does this provide a clear trail of accountability, but it also helps to future-proof your operations. Plus, if you ever find yourself in the hot seat (pun intended) during an audit, thorough documentation can be your saving grace.

- Implementing Error Handling Protocols

Let’s face it – errors happen. Whether it’s a malfunctioning temperature probe or a hiccup in your monitoring system, it’s essential to have robust error-handling protocols in place. Establish clear procedures for identifying, reporting, and resolving errors in your temperature monitoring process. This proactive approach not only minimizes the impact of errors on your data integrity but also demonstrates your commitment to quality and accuracy.

- Fostering a Culture of Accountability

Data integrity isn’t just a solo act – it’s a team effort. Foster a culture of accountability within your organization, where every team member understands their role in maintaining data integrity. Encourage open communication, transparency, and a willingness to speak up if something doesn’t seem quite right. By empowering your team to take ownership of data integrity, you create a collective mindset dedicated to excellence.

- Staying Ahead of Potential Pitfalls

Forewarned is forearmed, as they say. Take proactive measures to identify and address potential pitfalls in your thermal validation process before they become full-blown problems. Conduct risk assessments to pinpoint areas of vulnerability and develop mitigation strategies to minimize the likelihood of errors or discrepancies. By staying one step ahead, you can nip potential data integrity issues in the bud and keep your temperature logs running smoothly.

- Continuous Learning

The world of data integrity is a vast and ever-changing landscape. Embrace a mindset of continuous learning and improvement to stay at the top of your game. Attend workshops, webinars, and conferences to stay up to date on the latest trends, technologies, and best practices in thermal validation. Encourage your team to pursue professional development opportunities and share their newfound knowledge with the group. After all, knowledge is power – especially when it comes to safeguarding the integrity of your data.

- Regular Maintenance Checks

Just like you wouldn’t drive a car without regular oil changes, you shouldn’t rely on temperature monitoring devices without regular maintenance checks. Schedule routine inspections and calibration checks for your monitoring equipment to ensure they’re operating at peak performance. This proactive approach not only helps prevent equipment malfunctions but also maintains the accuracy and reliability of your temperature data.

Implementing Real-Time Alerts

Don’t wait until it’s too late to address temperature deviations – implement real-time alerts to stay ahead of potential issues.

Set up automated alerts that notify you immediately if temperatures stray outside of predetermined thresholds.

This proactive approach allows you to take swift corrective action, minimizing the risk of compromising the integrity of your samples or products.

Conducting Root Cause Analysis

When errors occur in your thermal validation process, don’t just sweep them under the rug – conduct a thorough root cause analysis to understand what went wrong and why.

Identify the underlying factors contributing to the error and implement corrective actions to prevent recurrence.

By addressing root causes instead of just symptoms, you can strengthen the integrity of your data and prevent similar issues in the future.

Engaging Stakeholders

Data integrity isn’t just a concern for scientists and technicians – it’s a collective responsibility that involves stakeholders across the organization.

Engage stakeholders from different departments, including management, quality assurance, and regulatory affairs, in discussions about data integrity and the importance of thermal validation.

Foster collaboration and open dialogue to ensure everyone understands their role in maintaining the integrity of temperature data.

Continuously Evolving Processes

The only constant in life is change, and the same holds for thermal validation processes.

Continuously evaluate and evolve your procedures to adapt to changing regulatory requirements, technological advancements, and organizational needs.

Solicit feedback from team members and stakeholders and be willing to adjust as necessary to improve the effectiveness and efficiency of your thermal validation efforts.

Parting Thoughts

From regular maintenance checks to real-time alerts and stakeholder engagement, these strategies will help you stay ahead of the curve and ensure the accuracy and reliability of your temperature data.

Maximizing data integrity in thermal validation might not be the most glamorous task, but it’s crucial for ensuring the safety and efficacy of our products. So, remember, keep it simple, stay consistent, and always have a backup plan.

Why is data integrity important in thermal validation?

How often should temperature readings be recorded during thermal validation?

What should I do if I suspect a temperature deviation during thermal validation?

How can I ensure the accuracy of temperature monitoring devices?

What should I include in my temperature monitoring log?

How can I ensure compliance with regulatory requirements in thermal validation?

What are some common pitfalls to avoid in thermal validation?

How can I stay informed about best practices and advancements in thermal validation?

About Incepbio

In addition to our Clean Room Validation services, Incepbio Private Limited offers comprehensive support for thermal validation to ensure the integrity of your controlled environments.

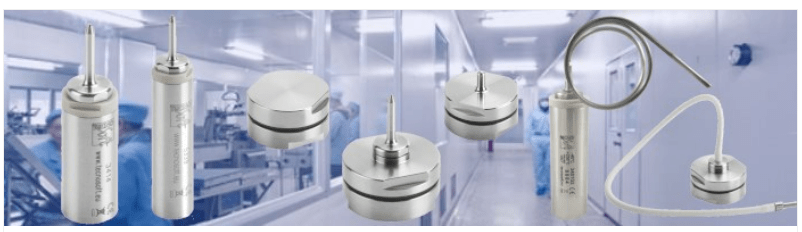

Our experienced team utilizes state-of-the-art equipment and industry-leading techniques to conduct thorough thermal validation assessments.

Whether you require temperature mapping, equipment qualification, or protocol development, we’re here to assist you every step of the way.

With our expertise in regulatory compliance and quality assurance, you can trust Incepbio to provide reliable and accurate thermal validation solutions that’s tailored to your specific needs. Let us help you maintain the highest standards of temperature control and data integrity in your facilities.